Trainer Insights - Passivhaus is mostly about quality!

The Passivhaus standard delivers comfortable, healthy environments with minimal energy use by prioritising quality in design and construction – but quality shouldn’t be voluntary; it should be for everyone.

Coaction trainer LIAM MCDONAGH-GREAVES shares his personal experience on the challenges of buying newbuilds and how quality assurance comes as standard with a Passivhaus…

A friend of mine moved into a brand-new house, built in 2019 by a UK volume housebuilder. Naturally, she hoped that it would be thermally comfortable and healthy, even if nowhere near as energy efficient as a Passivhaus building. Unfortunately, it was even less energy efficient than it was supposed to be, and more importantly, she experienced significant mould problems at the ceiling to wall junction in all 3 bedrooms and the bathroom soon after moving in. [Figs. 1 and 2]

Fig. 1: Mould in a bedroom. This is after significant cleaning, but the extent is obvious.

Fig. 2: Mould in bathroom

What were the problems?

When my WARM colleague and I visited, we found a number of defects:

- The loft insulation had not been pushed far enough into the eaves. This is likely to have been the primary cause of the mould on the ceilings meeting external walls. [Fig. 3]

Fig.3: Bottom layer of insulation at the eaves.

- The insulation had also not been installed tight against the party wall, leaving an air gap. This is likely to have accounted for the remainder of the mould issues. [Fig. 4 & 5]

Fig.4: Large gap between the loft insulation and the party wall

Fig. 5: Air admittance valve with large gaps around it.

- The duct from the bathroom extract fan to the roof terminal had either fallen off or had not been connected in the first place, so moist air was being exhausted into the loft space. [Fig. 6]

Fig. 6: En-suite extract ductwork not connected to roof terminal.

- Some of the insulation had not been fully unrolled.

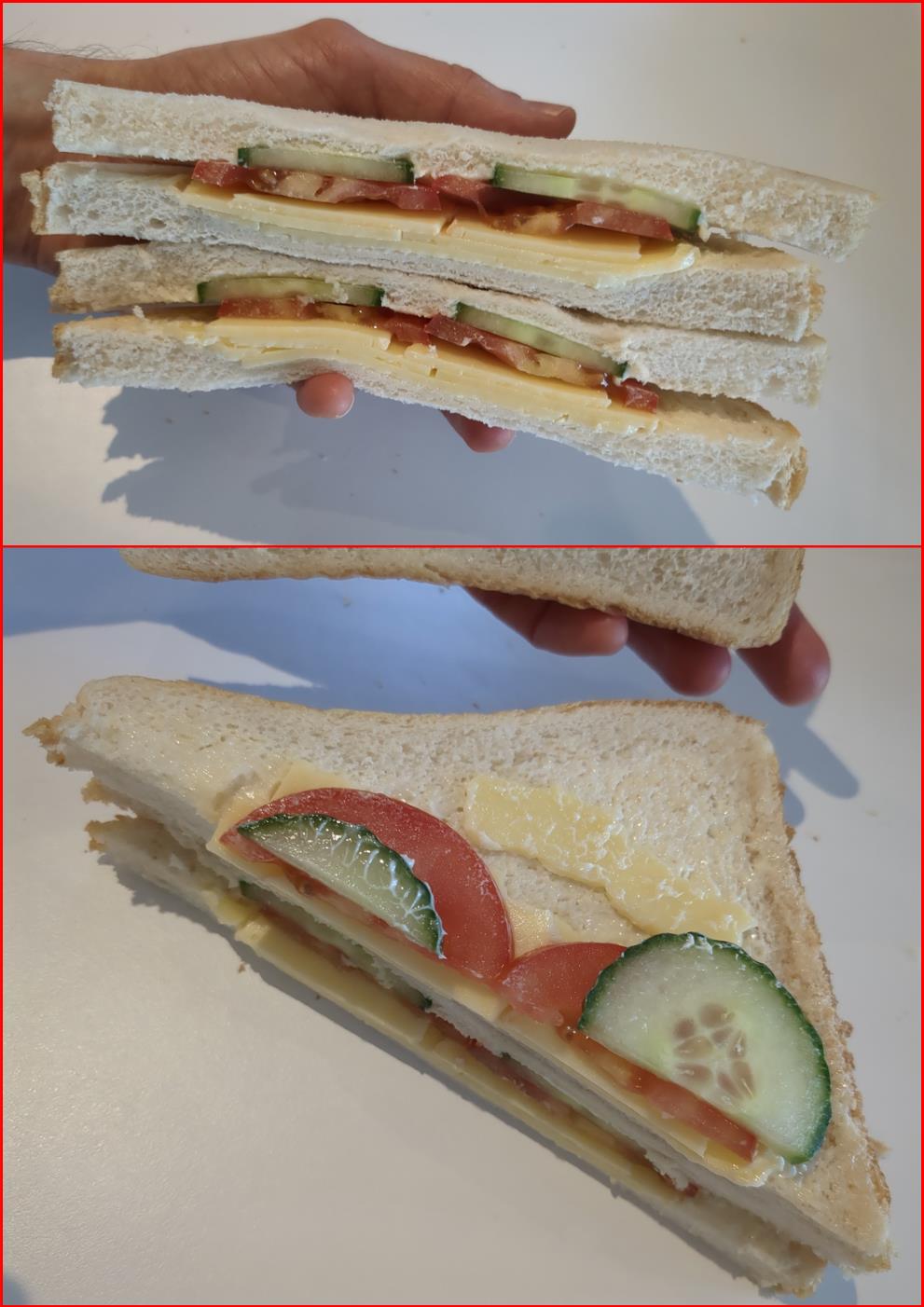

- When you stuck your head through the loft hatch, the insulation thickness looked fine. But on further investigation, it got thinner as you got further from the loft hatch. (This is the construction equivalent of a sandwich with most of the filling pushed to the front edge!) [Fig. 7]

Fig. 7: If bad builders made sandwiches.

Warranty provider’s response

Our friend, not knowing any of the above, had complained about the mould issues several times, but to no avail. She was asked to send photos of the outside of the house and the loft space, but the loft had no lighting or crawl boards, presenting a barrier to providing the requisite documentation. She was told by the warranty provider that the problem was “user error”. Call me Mr. Cynical, but the tactic seems to have been to deny and prevaricate until the complainant gives up.

Resolution?

My colleague, Karl Parsons, ultimately wrote a detailed technical report for our friend, which she submitted to the warranty provider. The defects were corrected, and within weeks, the mould issues had vanished. It didn’t take much – just doing the job properly. Most people don’t have mates who are construction professionals to lean on, though, and they shouldn’t have to.

The solution: better quality assurance

There are measures in place to guard against such issues at the design stage. For instance, junction details must, in effect, achieve a surface temperature factor (fRsi) of at least 0.75 to minimise the risk of mould growth. But if no-one is checking that the building is constructed according to the design, the quality assurance process falls over. These issues escaped both the housebuilder’s own quality checks and those of Building Control.

When you pay for Passivhaus certification, you are buying top-notch quality assurance, ensuring that you get the building you have paid for.

We can do better

If you want to build better discover a proven fabric-first approach to low-energy building with our CONTRACTOR & CERTIFIED PASSIVHAUS TRADESPERSON COURSE, designed for contractors at a supervisory or management level and their supply chains. You'll develop skills to deliver successful Passivhaus builds on-site, whether large or small